As the Internet of Things (IoT) evolves, some Applications have fast-tracked their way into the spotlight as a result of the global pandemic.

Devices are connecting humans like never before from remote work and learning to streaming video and gaming content. In addition, in-person visits to the doctor have in some cases been replaced by telemedicine, so much so that Forrester predicts that patients will attend over one billion virtual care visits this year.

Additionally, the sudden surge in online shopping has impacted the supply chain. Today, these connected things are helping humans who use them, but in the future, more and more automated systems and IoT devices will emerge in factories and services such as touchless delivery where robots or machines handle all the work without humans.

But that’s not all that’s changed. As these IoT Applications propel into the mainstream, there are changes impacting how IT architects design the underlying storage that enables them.

What’s Changing in the IoT Data Journey?

Automation and Supply Chain Resilience

Consider the data demands of distribution and fulfillment in the supply chain: they’ve been massively disrupted because of the impact the pandemic has had on shipping conditions and distribution centers. Before COVID-19, typical requests would go to a central data center where the request would be disseminated to the biggest hub closest to the consumer with most of the supplies in stock. The result: a two-day delivery that set the standard for the industry so long ago.

But even that has gotten significantly more complex with the enormous surge in demand for shelter-in-place supplies, groceries, electronics, and so on. Massive distribution is a challenge because of the sheer volume of requests. However, it’s not the technology that’s led to longer delivery times; it’s the human factor that has not been able to keep pace. Systems in the supply chain rely heavily on humans to fulfill orders, especially in the “last mile.”

Automation can help move parts faster amid these accelerated demands. Automated IoT devices such as robots or autonomous vehicles can assist from the factory to your doorstep. As these devices both generate and rely on increasing volumes of data, storage is essential at every step in the data journey.

Connectivity: The Need for Speed

Connectivity speeds, reliability and large bandwidth for multiple people with multiple IoT devices are increasingly important in today’s new world. The ability to access data when you need it and quickly get insights is critical. Data infrastructure must be set up to ensure data can be transmitted, received, stored and analyzed when and where it’s needed. The closer it is to the source, the less latency there is, which translates into faster time to insights and value.

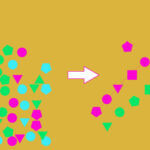

The aim of companies working with a vast array of IoT devices is to place specific storage solutions where they are most needed to ensure that data is handled appropriately across its entire IoT data journey. Edge computing is more important than ever before as it helps deliver a positive user experience for Applications like HD videoconferencing, distance-learning, or telehealth.

Acceleration of 5G

The pandemic may be a catalyst that will accelerate the demand for 5G. The newly dispersed workforce still requires quality virtual connections, which will continue to drive demand for high-speed, low-latency connectivity everywhere, even on the go.

5G is also helping industrial IoT move forward by enabling more reliable autonomous manufacturing processes with new standards for ultra-low latency in factories. The processing power required for 5G is tremendous, and along with that comes the requirements for data storage. IoT devices such as robots and cameras are being used to track assets throughout the supply chain and collect data such as temperature and vibration to track shipping container openings. Using IoT-enabled devices on transportation routes can help optimize route planning by collecting in-transit, supply chain data.

AR and VR Expand Beyond Gaming

Since the pandemic, AR/VR is being increasingly used in more Applications, connecting people with connected devices such as cameras, tablets, and phones.

For companies developing new technologies or running a global business, the required expertise won’t always be in the same location of a problem that needs to be solved.

Instead of flying an engineer halfway around the world, teams can turn to AR or VR to meet virtually in the same lab, looking at the same thing, on a common whiteboard while working in augmented reality.

In the post-pandemic world, AR and VR could make a new generation of remote viewership possible. Audiences might use AR and VR to immerse themselves in their favorite events, games, movies, or shows. With advancements in edge computing, a suite of technologies will enable the next generation of remote viewership, opening up new revenue possibilities for sports and performance artists, and reaching broader audiences.

Distance learning might utilize AR and VR to create immersive learning experiences. Online learning could become a standard extension for classroom-based education. Schools might partner with IT departments to create distance learning “tech kits” for their students, including take-home laptops, networking equipment, and desktop data storage solutions.

General-Purpose Architectures No Longer Cut It

Many businesses still use general-purpose architecture to manage their IoT data. But most often, general-purpose compute architectures do not fully meet the needs of IoT workloads. This method falls short of the accessibility, capacity, reliability, and scalability requirements necessary for IoT applications because a general-purpose, commercial architecture does not take into account the various elements an IoT system can face.

Purpose-built architecture uses devices, platforms, systems, and solutions that maximize the value of data for real-time IoT Applications. Your storage strategy has to be designed specifically for IoT. Consider a cell tower, an underground mine, or a windmill where IoT devices may be both remote and able to withstand harsh environmental conditions such as temperature or humidity. Storage cannot be an afterthought; instead, systems architects need to work with the storage experts early on to design an architecture that addresses the system’s unique needs.

IoT in the New Normal

The importance of storage is undeniable as it plays a role in all of these data scenarios, at home and in business settings and across the supply chain. It must be considered as part of an organization’s business strategy. Not only does storage support human and machine-to-machine communications, but when combined with AI, IoT and 5G, storage enables companies to access data quickly to gain insights. Access to such data, at the right time and at the right place, will be important as new post-pandemic business models develop in the new normal.

Related Podcast Episode

Related Podcast Episode

Related Applications

Related Applications

Latest IoT News

Latest IoT News