Design and Manufacturing is profoundly impacted by the digitization of a physical thing.

Digitization of a physical thing is more than the Internet of Things (IoT). More than connecting the thing and performing predictive maintenance. We saw this in part 1 of this series.

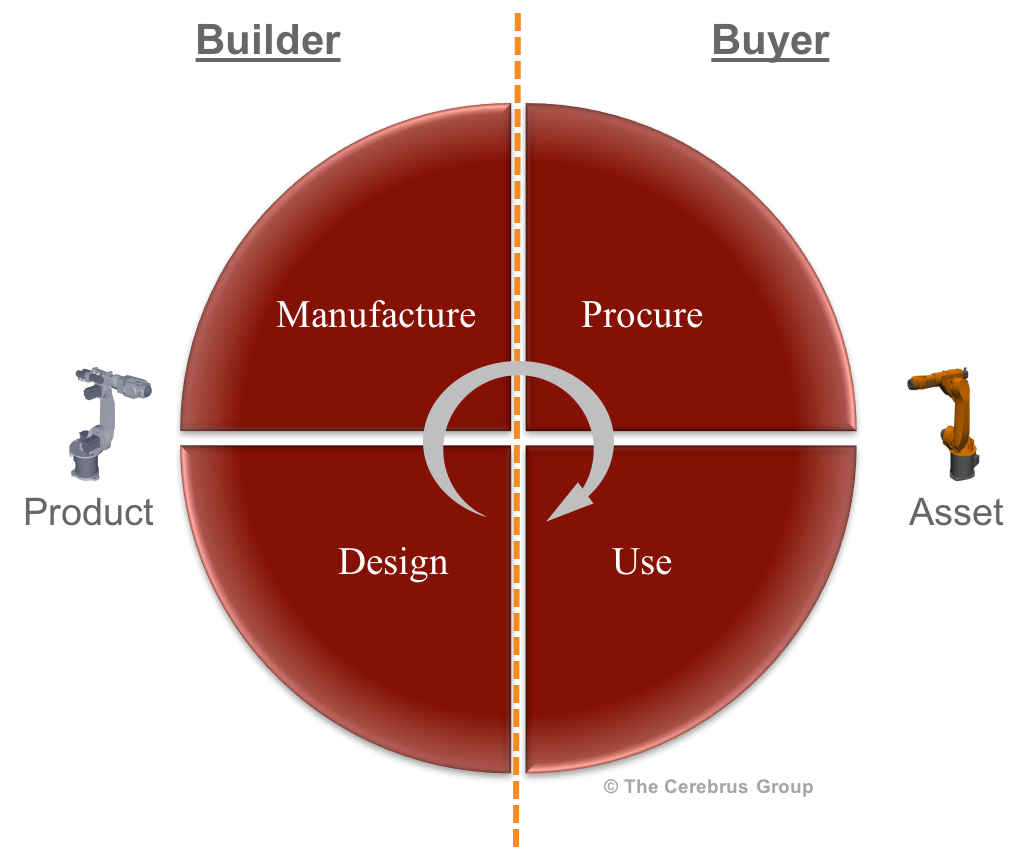

In part 2, we will take a closer look at the impact of digitization on the production of the thing and the implications on the ecosystem involved. In part 3, we will look at the consumption of assets.

Designing a Cyber-Physical Thing

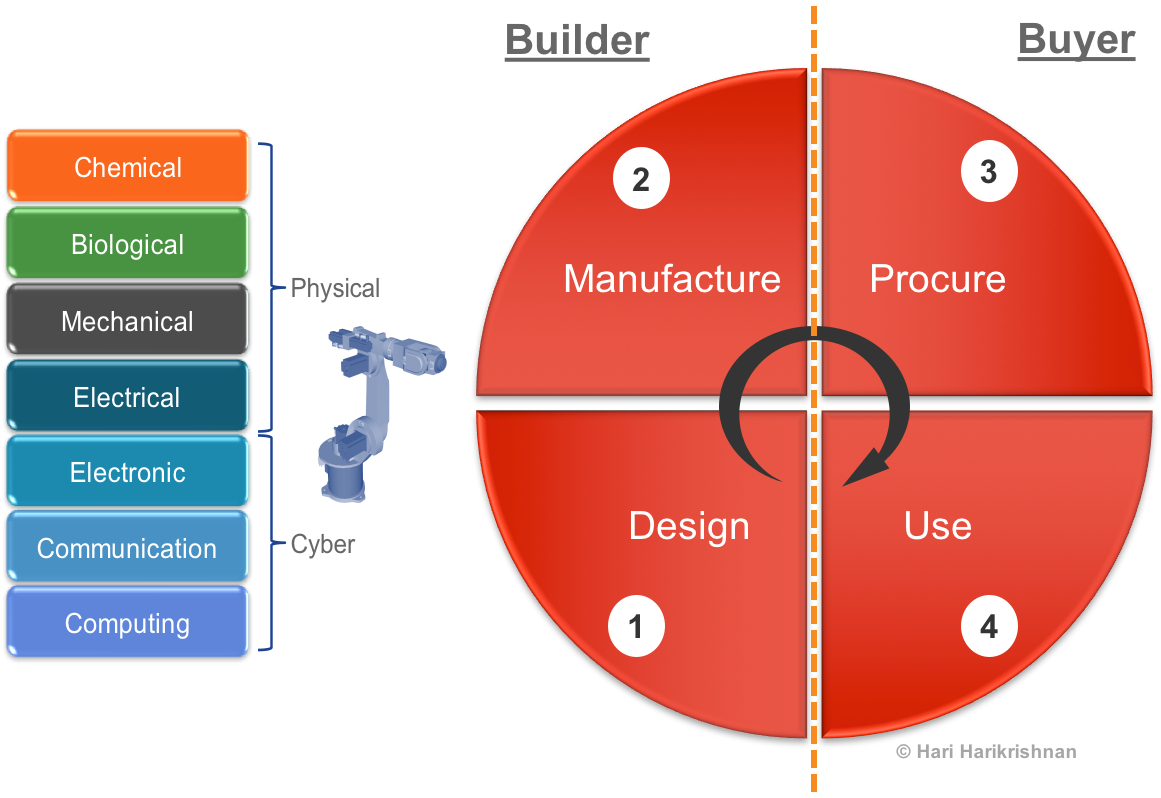

The convergence of materials with information technology makes products not just physical as they used to be, but cyber-physical or cyber-organic.

The science and technology stack (“STEM stack”) on the left shows physical (“analog”) parts of the product and the cyber parts of the product. Designing a cyber-physical thing requires juxtaposing the following:

- Materials: Blending of materials new and old. New plastics, polymers, and fiber herald a revival of material sciences and new products.

- Processes: Taking advantage of additive manufacturing (“3D Printing”) and robotics in fabrication to build new products and geometry.

- Electronic and Industrial Blend: Integrating computing and communications technologies from the semiconductor world with industrial world in both design and manufacturing.

- Ease of consumption: This goes beyond simple user experience (UX) and aesthetics. Ease of consumption spans the lifecycle of the asset, as the buyer, operator, and user interacts with the product and its maker. It spans procurement to use to decommissioning. Subscription models allow the product to be consumed as a service rather than via classic transactional product purchases and owner operations.

Product design goes from computer-aided to compute-integrated while product itself becomes service-oriented.

All this requires not just cyber-physical product thinking, but a systems-thinking about cyber-physical systems.

Manufacturing a Cyber-physical Thing

New manufacturing processes (e.g. Robotics and 3D printing) with even tighter process control (using AI) bring more flexibility to fabrication so the product can be made and delivered to the buyer not only at lower cost but much faster.

They (and their AI-enhanced Digital Twins of the factory and supply chain) enable mass customization, avoid waste and defects, alter forward and reverse logistics, increase durability, increase utilization of expensive supply chain assets, reduce parts, and provide an outward focus (through visibility, traceability, and faster and better decisions) to the builder and buyer if anything were to miss a beat.

Production Ecosystem Impact

A few of the implications for firms in the production ecosystem are as follows.

OEMs: Thing Makers

The convergence of materials and smarts (“mechatronic” devices) requires a design-rethinking. Simulations and design automation for cyber-physical products move beyond traditional thermal and structural integrity to signal integrity and heating/cooling considerations for mechanical, electrical, electronic, and communications sub-systems.

New geometries are possible from stage 2 innovations like Robotic Additive Manufacturing. Contract Manufacturers (CM) from stage 2 partner with OEMs as Original Design Manufacturers (ODM).

Software Makers: Design & Lifecycle Management

Firms like Autodesk, ANSYS, SolidWorks, and Cadence add IoT capabilities to their products. Computer-aided Design (CAD) and Electronic Design Automation (EDA) firms extend into each other’s turf. e.g. ANSYS product line has EDA products.

This line-extension dynamic continues on to the manufacturing stage and beyond in PLM and ALM (Product / Asset Lifecycle Management) software.

Classic CAD firms and electronic CAD firms (ECAD or EDA) are tussling. Autodesk bought an EDA firm in 2016. Industrial IoT firms are buying or investing in small software or systems companies.

Manufacturers: Contract and Original Design

Contract manufacturing worlds of industrial and electronic equipment are nudging closer due to the digitization of the product. Contract manufacturing in electronic manufacturing services industry have been moving closer to OEMs by turning into ODMs (Original Design Manufacturing). e.g. Qanta, Foxconn, Flex, Jabil.

Collaborations across contract manufacturer types and OEMs, whether industrial or electronic, is poised to strengthen in the digital age.

Summary

Digitization of a Thing requires us to rethink about its entire lifecycle, from design to manufacturing to procurement and operations. Design and manufacturing are impacted by the entire “STEM stack” coming together to form mechatronic systems.

Product strategies including line extensions, M&A’s, and sourcing strategies change for OEMs as the thing lifecycle is digitized. Greater collaboration and consolidation within the OEM, contract/design manufacturing, and design and lifecycle software is in its early stages.

In part 3 of this series, we will examine how consumption changes for a digitized thing.

New Episode

New Episode

Latest IoT News

Latest IoT News